Auto ID technology (Automatic Identification Technology) plays a significant role in helping pharmaceutical companies achieve compliance with the Good Automated Manufacturing Practice (GAMP) guidelines. Let me explain it in simple terms:

What is GAMP? GAMP stands for Good Automated Manufacturing Practice. It’s a set of guidelines and practices that pharmaceutical companies follow to ensure the safe and consistent production of medicines and other healthcare products. GAMP helps make sure that the machines and computers used in the production process are working correctly and reliably.

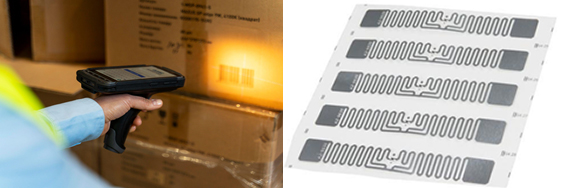

How does Auto ID Technology Help? Auto ID technology includes things like barcodes, RFID (Radio-Frequency Identification), and QR codes. These technologies help pharmaceutical companies in several ways:

Tracking and Tracing: Auto ID technology allows pharmaceutical companies to label and track every product, ingredient, or batch throughout the manufacturing process. This means they can see where everything comes from and where it goes. It’s like giving each medicine bottle a special code that can be scanned and checked at every step.

Quality Control: Auto ID technology helps in quality control. It ensures that the right ingredients are used in the right amounts and that everything is mixed or produced correctly. If something goes wrong, it’s easier to find and fix the problem quickly.

Reducing Errors: Humans can make mistakes, but machines that read barcodes or RFID tags are very good at it. Using Auto ID technology reduces the chances of making mistakes in the manufacturing process.

Data Management: GAMP requires companies to keep lots of records about how their products are made. Auto ID technology makes it easier to collect and store this information digitally, which is more accurate and efficient than doing it by hand.

Compliance: GAMP guidelines have specific requirements for using technology to ensure safety and quality. Auto ID technology helps companies meet these requirements and stay compliant with the rules.

In short, Auto ID technology helps pharmaceutical companies make their products correctly, keep track of everything, and follow the GAMP guidelines to ensure that medicines are safe and effective for people who need them. It’s like having a super helper that makes sure everything is just right in the medicine-making process.

Following are the application areas

- Gown Tracking System (GTS) : RFID based gown tracking system is being used to meet USFDA 21CFR Audit compliance.

- Line Clearance System : Using Barcode based Computer Tabs to validate, authenticate and store information and images before start of each batch.

- Intervention tracking System : Tracking each and every intervention during the batch manufacturing and recording the same for audit purposes.

- Raw Material Stores Management System (MITS) : Material Information tracking system : capturing all the activities during life cycle of each raw material till the time its issued or dispensed for the production against the material requisition. Tracking all the stages like Inward, Labelling, Quarantine, QC, Rejection, Ok, location identification, capturing weight of each material dispensed etc….

- Finished Goods Warehouse Management System (WMS) : Tracking the material movement in the Mother Warehouse, Child Warehouse. Tracking Who, what, where, when, how etc…Maintaining material in FEFO (First Expiry First Out) basis etc..

- Environmental Monitoring System : Maintain and record all the environmental parameters as per the policy of different locations.

- File Tracking System : RFID based tracking all the files with different people