In the fast-paced world of modern business, efficiency and accuracy are necessary. Barcode technology plays a crucial role in streamlining operations and enhancing productivity across various industries. To ensure seamless barcode printing, choosing the right barcode ribbons is essential. In this guide, we’ll explore the factors to consider when selecting barcode ribbons for different applications and labels.

Understand Your Printing Environment

Before diving into the world of barcode ribbons, assess your printing environment. Consider factors such as the type of printer you use (thermal transfer or direct thermal), printing volume, and the working conditions (temperature, humidity). Understanding your environment is the first step in choosing ribbons that can withstand specific conditions and deliver optimal performance.

Identify the Right Ribbon Material

Barcode ribbons come in various materials, each catering to specific needs. The two main types are wax, wax-resin, and resin ribbons.

-Wax Ribbons: Ideal for standard paper labels, wax ribbons are cost-effective and provide good print quality. They are suitable for applications with minimal exposure to harsh conditions.

– Wax-Resin Ribbons: Offering a balance between durability and affordability, wax-resin ribbons are suitable for semi-gloss and synthetic labels. They provide enhanced resistance to smudging and scratching.

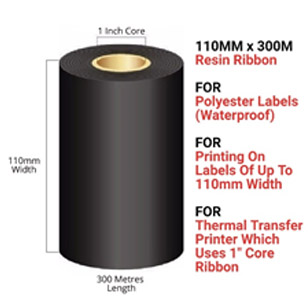

– Resin Ribbons: If you require high durability and resistance to chemicals and extreme conditions, resin ribbons are the best choice. They are perfect for labels used in healthcare, automotive, and outdoor applications.

Consider Label Material

The material of your labels plays a crucial role in determining the type of ribbon you need. For paper labels, wax ribbons are sufficient. For synthetic labels or those with a glossy finish, consider wax-resin or resin ribbons to ensure longevity and readability.

Evaluate Print Quality Requirements

The clarity and accuracy of barcode printing are vital for successful scanning. Consider the resolution of your printer and the intricacy of your barcode design. High-resolution printers work well with all types of ribbons, but if you have specific print quality requirements, such as small font sizes or intricate graphics, a resin ribbon might be the best choice.

Assess Longevity and Durability Needs

The durability of barcode labels is critical, especially in industries with rigorous conditions. If your labels will be exposed to chemicals, abrasion, or outdoor elements, opt for resin ribbons. They provide a protective layer that ensures longevity and readability even in challenging environments.

Compliance and Industry Standards

Certain industries have specific requirements for barcode labeling, including size, format, and durability. Ensure that your chosen barcode ribbons comply with industry standards and regulations. This is particularly important in sectors such as healthcare, logistics, and manufacturing, where accurate barcode scanning is integral to operations.

Test Before Committing

Before committing to a bulk purchase, conduct a trial run. Most ribbon manufacturers provide sample rolls for testing. This allows you to evaluate how well the ribbon performs in your specific environment and with your chosen label material.

Choose a ribbon colour that’s best suited for your labels

There are variety of options available in terms of ribbon colours. The colours available are: Black, white, Red, Blue and Green.

Make sure that the ribbon’s width is 5mm longer than that of label on both sides

This ensures longevity of printhead and accurate printing on the label.

Consider an optimal temperature for printing, as the melting points of resin and wax ribbons differ

Wax ribbon typically has lower melting point, whereas resin ribbon requires a high melting point so it is important to adjust the printhead temperature for printing. This ensures efficient and best results in label printing.

Conclusion:

Choosing the best barcode ribbons for your applications and labels is a strategic decision that directly impacts the efficiency and accuracy of your operations. By understanding your printing environment, considering ribbon materials, evaluating print quality, and assessing durability needs, you can make an informed choice that enhances your barcode system’s performance.

Investing in high-quality barcode ribbons tailored to your unique requirements ensures that your labels withstand the test of time, contributing to the overall success of your business operations. Select wisely, and let the right barcode ribbons be the key to unlocking efficiency in your barcode labeling processes.